A nodal-integration-based Finite Element Method for the simulation of thermo-mechanical processes

The prediction of the metallurgical and mechanical consequences induced by thermo-mechanical manufacturing processes, requires highly non-linear thermo-elastoplastic or viscoplastic numerical simulations. While these simulations have long concerned relatively simple geometries, located in the vicinity of the affected areas, industrial companies now wish to work on real geometries generally complex and 3D.

But taking into account elastoplastic behaviors based on the von Mises criterion can induce locking phenomena, associated with plastic incompressibility, requiring the use of special finite elements (reduced integration, mixed formulations, etc.). The need to use these elements then leads to very significant additional costs in particular due to the meshing phase.

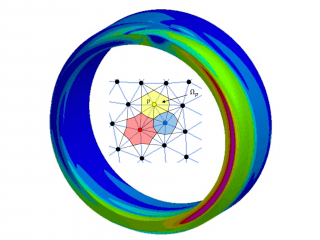

With the main objective of developing a numerical method offering the best possible compromise between the duration of the study (including the phases of meshing, resolution and analysis of the results) and the precision of the results, we propose a new finite element method based on nodal integration and tetrahedral meshes (NIFEM: Nodal-Integration-based Finite Element Method). The existence of high-performance tools for automatic meshing in tetrahedrons gives this type of finite element an indisputable economic advantage. And the choice of nodes as integration points seems optimal regarding the volumetric locking phenomenon.

The choice of nodes as integration points is not new. We find this idea in particular in Dohrman et al [1], Krysl and Zhu [2], in the NS-FEM method (Node-based Smoothed Finite Element Method) [3] or in meshless methods [4]. These methods are mainly distinguished by the way of calculating the nodal deformations. We show that in the case of a tetrahedral mesh, some of these methods are in fact equivalent [5]. The calculation of the stresses on the external surfaces or at the interface between two materials, very imperfect with the original method, is then improved thanks to a specific integration algorithm of the constitutive equations of the material at these points [6].

A thermo-metallurgy module, compatible with the mechanical calculation module of NIFEM, is developed. The heat equation is formulated in enthalpy [7] to reproduce the phenomena of recalescence. All state variables (temperature, phase proportions, etc.) are calculated at the nodes.

Finally, as many thermomechanical processes involve moving loads (welding, rolling, etc.), an original algorithm for calculating the quasi-steady mechanical states for these problems is proposed.

References

[1]. Dohrmann CR, Heinstein MW, Jung J, Key SW, Witkowski WR (2000) Node-based uniform strain elements for three-node triangular and four-node tetrahedral meshes. Int J Numer Methods Eng, 47:1549–1568

[2]. Krysl P., Zhu B., Locking-free continuum displacement finite elements with noda lintegration, Int. J. for Numer. Meth. In Eng., 2008,; 76: 1020-1043.

[3]. H. Yang, X. Y. Cui, S. Li, Y. H. Bie (2018), A stable node-based smoothed finite element method for metal, Computational Mechanics, https://doi.org/10.1007/s00466-018-1641-2

[4]. Jiun-Shyan Chen, Cheng-tang Wu, Sangpil Yoon, and Yang You. A stabilized conforming nodal integration for Galerkin mesh-free methods. Int. J. for Numer. Meth. In Eng., 2001, 50, 435-466.

[5]. Jia, Y., Bergheau, J.-M., Leblond, J.-B., Roux, J.-C., Bouchaoui, R., Gallée, S., & Brosse, A. (2020). A new nodal-integration-based finite element method for the numerical simulation of welding processes. Metals, 10(10), 1-18. doi:10.3390/met10101386

[6]. Jia, Y., Leblond, J.-B., Bergheau, J.-M. (2022). Exact satisfaction of boundary and interface conditions in nodal-integration-based finite element methods. Comptes Rendus Mécanique 350 (G1), 57-83

[7]. Leblond, J.-B, Bergheau, J.-M., Lacroix, R., & Huin, D. (2017). Implementation and application of some nonlinear models of diffusion/reaction in solids. Finite Elements in Analysis and Design, 132, 8-26. doi:10.1016/j.finel.2017.04.004