Advances in testing and measuring architected materials

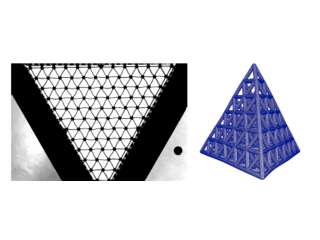

One of the definitions of architected materials is the existence of a meso scale, between micro and macro ones [So mera, 22]. Their mechanical advantages were highlighted by Ashby [97], but nature was already making extensive use of them (bones, wood, etc.), and large-scale architected structures were built in the 20th century. However, the availability of new manufacturing methods now makes it possible to produce smaller meso-scale structures, thereby broadening their fields of application. The architected material studied here is a regular lattice with triangular (2D) or tetrahedral (3D) meshes. With no mode without rigidity, even if articulated, it is a tensional lattice intended for structural applications that perform well in terms of specific elasticity and resistance.

While granular materials (concrete, rock, etc.) are weakened by expansion, engineered materials are sensitive to contraction. Before breaking, the beams of which they are composed may buckle in regular patterns larger than the primary pattern [Bertholdi, 08]. This buckling has the advantage of storing a lot of energy in a reversible man ner, but limits load-bearing capacity. In any case, knowledge of the linear elastic domain is essential for engineers. However, both calculations and tests on the subject are still in their early stages.

Existing tests usually consist of compressions between plates on dense planes. However, Dassonville’s testing device [20] stands out due to its design, which imposes deformation at the edges, and its ability to explore the deformation space. A new testing device, allowing the linear elasticity limit surface to be investigated, will be presented. It has a triangular geometry similar to that of the mesh, allowing the use of a simple one-dimensional testing machine and various innovations to achieve regular Cauchy-Born boundary conditions. The first validation tests of the setup will be shown. The buckling modes obtained for hydrostatic loading will be compared with Jeanneau’s computational predictions [23]. It can be observed that, unlike conventional tests, the new setup does not induce localization but forces the regular solution at the edges.

The other difficulty in testing these materials is shape measurement, at rest for detecting shape defects or under load for measuring elasticity and bifurcations. Conventional methods are not directly transferable. Image correlation measurements are suitable. In 2D, conventional DIC with speckle is not very suitable due to the small observable surface area. On the contrary, VIC benefits from the long edges of the beams. In 3D, the difficulty arises from the fact that the central cells have a low-contrast tomographic signal. The 3D-VIC method [Calmettes, 25], based on a few 2D X-rays radiographs, does not use the reconstructed 3D image that generates artifacts. It has made it possible to measure the sub-pixel shape defects of a tetrahedral sample with 6 cells per side.

Bertoldi, Boyce, Deschanel et Mullin. Mechanics of deformation-triggered pattern transformations and superelastic behavior in periodic elastomeric structures. J. Mech. Phys. Solids 2008

Calmettes, Fran¸cois et R´ethor´e. Shape measurements of lattice materials from few X-ray radiographs using the 3D Virtual Image Correlation method. Exp. Mech., 2025

Dassonville, Poncelet et Auffray. Toward a homogenizing machine. Int. J. Solids Struct., 2020 Gibson et Ashby. Cellular solids : structure and properties, 1997

Jeanneau, Combescure et Fran¸cois, Homogenized elasticity and domain of linear elasticity of 2D architectured materials. Int. J. Solids Struct., 2023

Somera, Poncelet, Auffray et R´ethor´e. Quasi-periodic lattices : pattern matters too. Scripta Mat., 2022