Full-scale Microstructural Simulation of Turbine Blades: From Crystal Plasticity to Machine Learning.

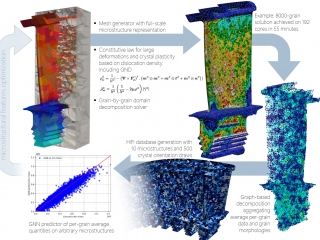

Reducing emissions from air transport while ensuring safety requires the design of ever more efficient engines. A key lever lies in a better understanding and control of critical materials, such as turbine blade superalloys, which operate under extreme conditions. In this work, we develop a numerical simulation framework that explicitly incorporates the crystalline microstructure at the scale of the actual component. By coupling crystal plasticity with adaptive meshing and large-scale parallel computing, we simulate the behavior of blades containing up to several tens of thousands of grains. The generated results are then used to train graph neural networks capable of predicting, at reduced computational cost, the local mechanical responses as a function of microstructural features. This approach paves the way for improving the quality, robustness, and performance of critical components.

This research is conducted in collaboration with Christophe Bovet and Aurélien Vattré (ONERA, Université Paris-Saclay), and Lucie Lanciaux (Safran Aircraft Engines).

Graphical abstract: Full-scale crystal plasticity simulations of turbine blades, combined with graph neural networks, open new perspectives for predicting grain-scale responses and exploring microstructure-informed design strategies.