Séminaire : Christian Fagiano

Add to the calendarCharacterization and modelling of the effect of out-of-plane ply waviness defects on the mechanical behaviour of composite specimens.

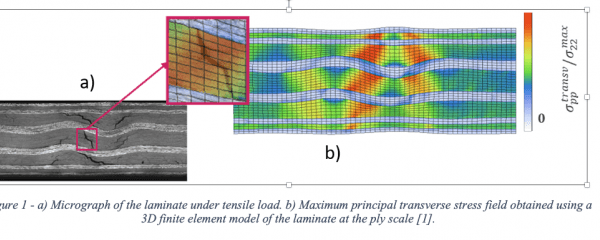

Structural parts made of laminated composite materials with long carbon fibers are increasingly used in a growing number of high-performance industrial applications. However, their manufacturing process can introduce various types of initial defects, potentially leading to significant reductions in mechanical properties. A common manufacturing defect in laminated composite structures is out-of-plane waviness of the plies, which can cause significant reductions in their mechanical strength due to premature failure by delamination. The effects on the property reductions depend on the characteristics of the waviness defects, i.e. their morphological parameters (length, amplitude, etc.) and their location within the part [1,2]. Predicting these effects is essential for defining reliable acceptance and certification criteria for structural parts in presence of initial out-of-plane waviness.

The purpose of this workshop is to present a modeling strategy to simulate the effects of out-of-plane waviness defects on the mechanical properties, the damage mechanisms and their evolution, and the ultimate failure load of laminated composites. Model predictions are validated through a comparative analysis with experimentally observed damage sequences. Compared to specimens without defects, delamination emerges as an important damage mechanism from the first damage onset onwards. In thermoplastic matrix composites, the defect triggers the onset of large cracks that extend through the entire ply thickness, while only small cracks are observed in the area without the defect. The modeling strategy is also applied to composite specimens with open holes and curved parts, both of which are particularly prone to ply waviness defects.